Frequent equipment failures can cause production stoppages. How is stability ensured?

Frequent equipment failures can cause production stoppages. How is stability ensured?

An independently developed lifecycle management system monitors equipment health in real time. With AI-driven predictive maintenance, potential failures are addressed early. For example, the edge-forming machine head failure rate was reduced from 7% to nearly zero, cutting annual downtime from 13 events to almost none, saving over USD 390,000 per line annually.

Can solar glass be produced thinner than 1.5 mm without compromising strength?

Can solar glass be produced thinner than 1.5 mm without compromising strength?

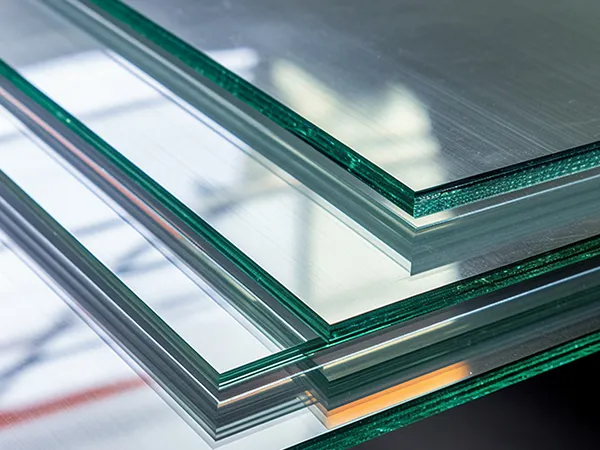

The ultra-thin solar rolled glass line has achieved stable mass production of 1.4 mm glass. Proprietary forming equipment and material formulations ensure both thinness and high impact resistance, reducing reliance on imports and lowering module costs for customers.

With energy costs exceeding 40% of production, how can consumption be reduced?

With energy costs exceeding 40% of production, how can consumption be reduced?

With energy costs exceeding 40% of production, how can consumption be reduced?

An intelligent combustion control system dynamically optimizes fuel and oxygen ratios in furnaces, improving thermal efficiency by 15%. Paired with an energy management platform for real-time analysis, annual energy savings reach USD 220,000 per line, while green factory standards further reduce carbon emissions.

Can customized solutions be provided for non-standard glass production lines?

Can customized solutions be provided for non-standard glass production lines?

For electronic displays, automotive glass, and solar applications, fully customized designs are available. For example, a 0.12 mm ultra-thin glass line for flexible displays (the thinnest worldwide) achieved a yield rate above 98%, supported by 166 patents for rapid response to complex requirements.