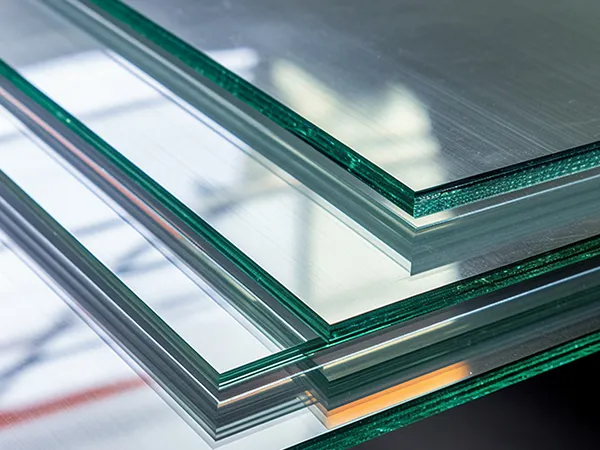

Automotive glass production lines are designed to meet the structural and performance requirements of different vehicle models. These systems can produce single-curved tempered glass, double-curved tempered glass, laminated glass, and more. The process starts with melting and shaping the raw glass, then continues with cutting and finishing. After that, the glass is carefully inspected and finally packaged. This glass processing equipment is used to produce windshields, side windows, rear windows, and sunroof glass. Each glass sheet is produced to be safe, long-lasting, and shaped precisely to fit the design of the vehicle.

- Laminated Glass (Windshields)

Raw glass → Cutting → Edging → Washing → Screen printing (black edges and logos) → High-temperature bending → Lamination (outer glass + inner glass + PVB film) → Pre-press and de-airing → Autoclave bonding → Final inspection → Packaging - Tempered Glass (Side Windows / Sunroofs)

Raw glass → Cutting → Edging/Drilling → Washing → Screen printing → Heating and bending → Tempering → Final inspection → Packaging

Automotive glass lines include all the machines that cover every stage, from melting raw materials to forming, processing, testing, and final packaging. The glass processing equipment must be accurate, safe, and efficient, and it’s usually grouped into six main categories.

Raw Material and Forming Equipment

- Melting Equipment

Float furnace

Electric or gas furnaces - Forming & Initial Processing Equipment

Tin bath and annealing lehr

Cutting systems:

• Mechanical cutters: diamond blade cutters for standard sizes (low cost but less precise).

• Laser cutters: for complex shapes such as windshield corners, with accuracy up to ±0.1 mm, reducing material waste.

Pre-washing machines: high-pressure spray with brushes, stainless steel design to avoid coating damage and ensure clean surfaces for further processing.

Heat Bending and Strengthening Equipment

- Bending and Curving

Bending furnace / press bending furnace

Press forming machines - Tempering Equipment

Physical tempering furnace

Chemical tempering furnace

Autoclave

Precision Processing and Functional Equipment

- Edging and Drilling

CNC edging machine

Automatic drilling machine - Coating and Printing

Magnetron sputtering coating machine

Screen printing machine - Lamination and Assembly

Flat lamination press

Glass turnover tables and robotic arms

Quality Inspection and Control Systems

- Online Inspection Equipment

AI-based visual inspection system

Ultrasonic flaw detector - Laboratory Testing Equipment

Impact testing machine

Environmental aging chamber

Packaging and Environmental Systems

- Smart Packaging Systems

Shockproof packaging machines

Intelligent storage solutions - Energy-Saving and Environmental Systems

Waste heat recovery boiler

Wastewater recycling system

Digitalization and Smart Control

- Digital twin platform

- Optimized cutting control system