Contact us any time

We're Happy to Help You!

Wherever you are, we’re here to provide support and solutions. Share your inquiries with us—we look forward to collaborating with you.

Contact Us

Our Glass Equipment Covers

How does the solar glass washing machine ensure the required level of cleanliness for different process stages?

How does the solar glass washing machine ensure the required level of cleanliness for different process stages?

The solar glass washing machine is equipped with lifting and frame mechanisms, conveyors, spray-and-brush units, air knives with fans, water supply systems, photoelectric limiters, and control cabinets. It adopts an innovative sectional spraying method that improves water efficiency and enhances the overall cleaning effect, meeting the cleanliness demands of each process stage.

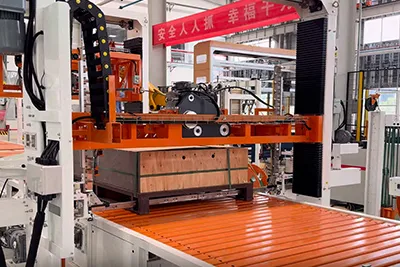

How is stable operation ensured in fully automatic packaging lines for entire glass stacks?

How is stable operation ensured in fully automatic packaging lines for entire glass stacks?

The automatic packaging line uses robotic arms to apply corner and side protectors, while the integrated sensors monitor and control the clamping force. Storage bins can hold up to three different protector sizes at once, with each side accommodating three bins to allow up to 12 hours of continuous operation without refilling. The bins are designed to be pulled out for refilling without stopping production. A specially designed arrow-type joining mechanism along the length direction further ensures smooth and stable operation.

How does the AGV glass transport system help reduce costs while maintaining high efficiency?

How does the AGV glass transport system help reduce costs while maintaining high efficiency?

AGV vehicles perform automatic operations from loading to unloading with minimal human intervention. They flexibly connect raw glass to processing lines and from processed glass to automatic packaging and warehousing. The transport system enables fully intelligent order scheduling and warehouse management, allowing unmanned operation throughout the process. By replacing manual work, it significantly reduces labor and training costs while increasing operational efficiency.