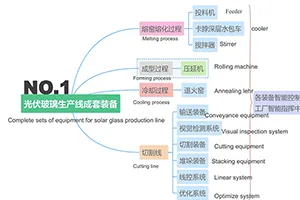

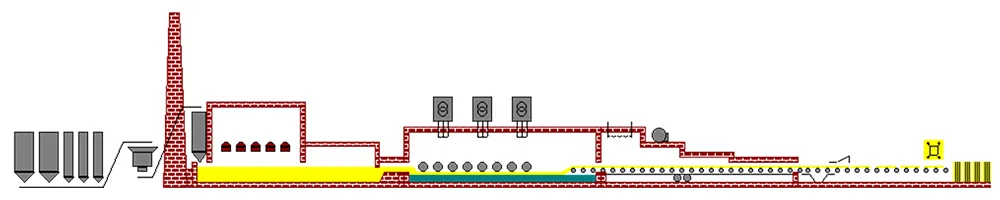

Flat glass production lines take raw materials through melting, forming, annealing, and cooling before the sheets are ready for further processing. Depending on the application, molten glass can be shaped using the float method or the rolling process. With these lines, we can produce glass sheets in a wide range of sizes and thicknesses, making them suitable for construction, automotive, solar energy, and many other industries.

Glass Forming

Glass Forming Batching

Batching Melting and Drawing

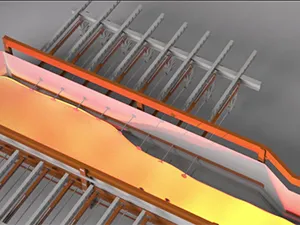

Melting and Drawing Glass Rolling

Glass Rolling Annealing

Annealing Cold End Equipment (including glass cutting, conveying, and stacking)

Cold End Equipment (including glass cutting, conveying, and stacking)