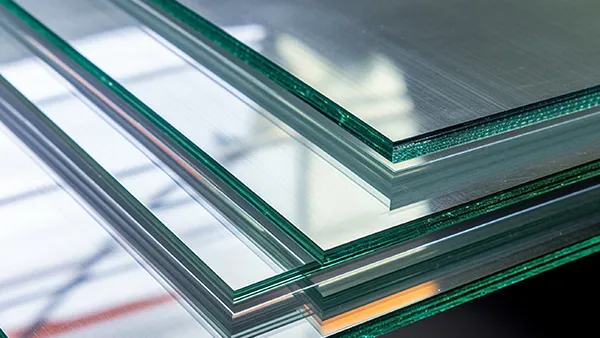

These glass production lines cover all the main steps needed to produce insulated glass, starting with cutting and cleaning the sheets and moving through frame making, lamination, and sealing. The glass manufacturing equipment is divided into five categories, each supporting a specific stage so that glass production stays efficient and the final product meets quality standards.

-

Cutting and Pre-Processing Equipment

Glass cutting machine

Glass edge grinding machine -

Washing and Drying Equipment

Glass washing & drying machine

Glass inspection conveyor -

Spacer Frame Fabrication Equipment

Aluminum spacer bending machine

Desiccant filling machine

Butyl coating machine -

Assembly and Pressing Equipment

Glass pressing machine / glass sheet assembly machine

Glass turning conveyor

Glass hot press machine -

Sealing and Gas Filling Equipment

Two-component sealing machine

Rotary sealant spreader

Automatic gas filling system -

Optional Integrated Automation Equipment

Automatic vertical/horizontal production line

Glass loading & unloading robot