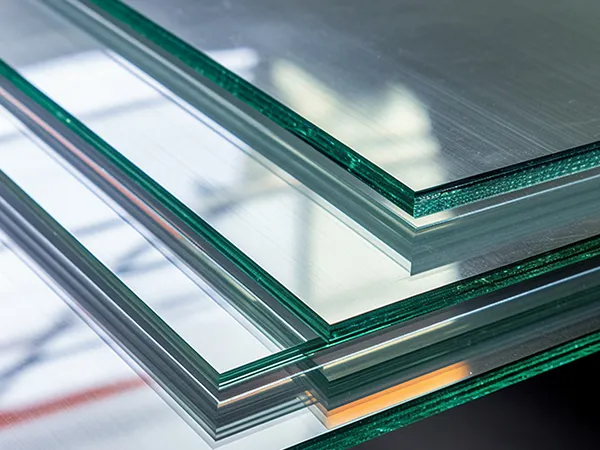

The electronic glass production line is made to meet the high standards of display glass. It makes sure the glass is thin, smooth on the surface, and strong enough to be used in modern screens. It improves the float process by adding sealed rolling technology and incorporates techniques from rolled glass production. This makes the forming more precise while also helping to keep production costs down. With this approach, the line can process ultra-thin glass down to 0.12 mm, as well as 0.55 mm STN-LCD substrates commonly used in liquid crystal displays. Ultra-thin processed glass is widely used in smartphones, tablets, laptops, and flat-panel TVs, as these applications require high clarity, durability, and light weight.

-

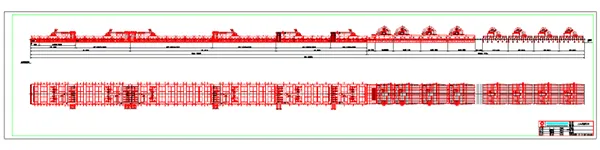

Annealing lehr layout

Annealing lehr layout -

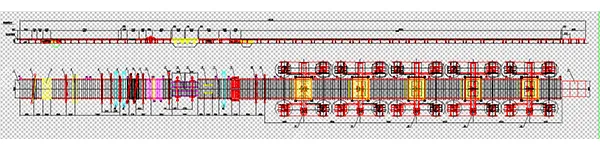

Cold end process layout

Cold end process layout

Batch charger → Melting (including melting & pre-refining) → Refining → Forming → Annealing → Inspection → Cutting → Cleaning → Packaging & Storage

-

Batch Charger (Glass Furnace Feeder)

Batch Charger (Glass Furnace Feeder) -

Float Glass Top Roller

Float Glass Top Roller -

Float Glass Annealing Lehr

Float Glass Annealing Lehr -

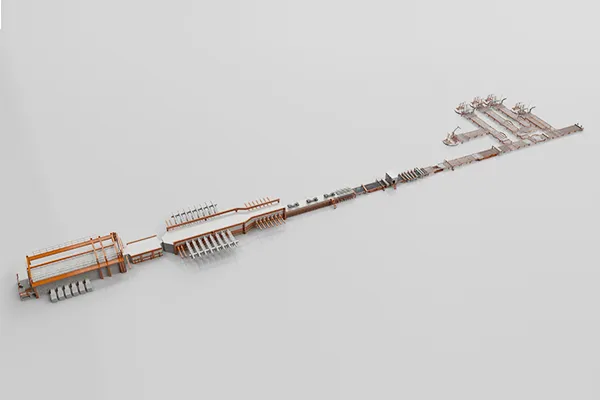

Cold End Equipment (glass cutting, glass conveying, glass stacking, etc.)

Cold End Equipment (glass cutting, glass conveying, glass stacking, etc.)