Contact us any time

We're Happy to Help You!

Wherever you are, we’re here to provide support and solutions. Share your inquiries with us—we look forward to collaborating with you.

Contact Us

Our Glass Equipment Covers

How does the batch charger keep the feeding steady?

How does the batch charger keep the feeding steady?

To keep raw materials flowing evenly, the system uses two drive stations and three clutches that can be combined in different ways. This makes the feeding shovels move together in sync, so the material is delivered continuously without interruptions.

What makes the dross box safe to use?

What makes the dross box safe to use?

The box is built with precise welding, so it doesn’t bend or lose shape, and then it’s heat-treated to make it even stronger. Inside, stronger stainless-steel plates are used, which can handle high temperatures without losing stability. This makes the box more reliable in daily use and lowers the risks that usually come with long-term operation.

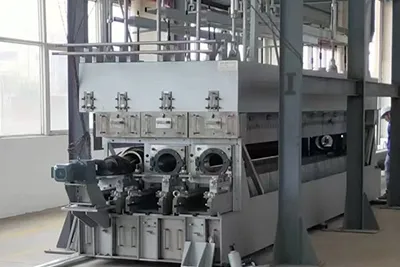

How does the solar glass rolling machine last longer under high heat?

How does the solar glass rolling machine last longer under high heat?

The lift-out roller table is built with a steel frame that has a circulating water system inside. This cooling setup prevents the frame from bending or losing shape when exposed to high heat. The bearings are also water-cooled, which reduces wear and extends their service life. Thanks to this design, the machine can keep running reliably even during long periods of continuous production at high temperatures.

How does the glass stirring system keep the glass uniform?

How does the glass stirring system keep the glass uniform?

The stirring depth can be adjusted depending on production needs. As the blades move, they generate vortexes in the molten glass that collide and mix together. This motion helps mix the molten glass thoroughly, making sure it stays even in both composition and quality before it goes into the forming stage.