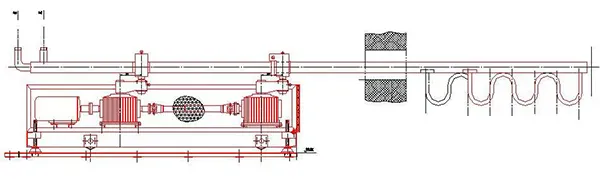

Glass Stirring System

Stirring mechanisms used in the flat glass manufacturing process for conditioning and homogenization of the molten glass

In glass melting, stirrers keep the molten glass well mixed before it reaches the forming stage. The mixing process reduces issues like streaks, bubbles, or uneven areas, helping the glass stay clear and consistent in quality. Depending on the plant layout and needs, manufacturers can choose between horizontal stirrers, which are easier to maintain, or vertical stirrers, which require less floor space. Both types of stirrers are meant to keep the molten glass consistent, which helps the line run smoothly and makes the final glass more reliable in quality.

The horizontal stirrer is used during flat glass production to keep the molten glass uniform in both temperature and composition. The stirring shaft extends into the furnace, with teeth positioned about 350 ± 50 mm below the surface of the melt. The shaft rotates and the teeth stirs the molten glass to generate circulating currents, which help distribute heat evenly, mix the glass thoroughly, and help remove bubbles. This results in more stable glass quality for the next stages of processing.

Specifications

- Stirring speed: 2-15r/min

- Stirring shaft: Horizontal stirring, rotating around the center

- Immersion depth: 300mm (depending on process)

Vertical stirrers are used in the forehearth (the chamber that carries molten glass from the furnace to the forming area) to keep molten glass stable and uniform before it reaches the forming stage. Vertical stirring mechanisms include the drive above the furnace, the stirrer with their support frame, and units for cooling and control. They also come with tools that make handling and maintenance easier. At the bottom, the blades move through the molten glass to create steady flows that keep the material well mixed. These flows collide and interact, which helps balance both the temperature and the chemical mix of the glass, giving producers more consistent results and higher quality output.

Specifications

- Stirring speed: 3-15r/min

- Stirring shaft: Vertical stirring, self-rotation

- Immersion depth: 185±50mm (depending on process)

- Functions: Rotation direction of stirring unit can be individually adjusted, and immersion depth is also adjustable