Frequent equipment failures can cause production stoppages. How is stability ensured?

Can solar glass be produced thinner than 1.5 mm without compromising strength?

With energy costs exceeding 40% of production, how can consumption be reduced?

Can customized solutions be provided for non-standard glass production lines?

How can efficiency be improved across multiple international factories?

A lean production management platform integrates MES, ERP, and 5G technology to enable one-screen global monitoring:

- Order scheduling efficiency increased by 30%

- AGV logistics cut labor costs by 50%

- Mobile apps enable remote production monitoring, already in use across Russia, Turkey, South Korea, and more than 10 other countries

Dependence on foreign engineers slows maintenance response. How is this addressed?

Four global service centers, including those in Turkey and Russia, ensure:

- 72-hour on-site response

- Multilingual technical training

- AR-based remote diagnostics and direct spare parts supply for over 100 lines, reducing downtime by 90%

How is cutting precision improved to reduce waste?

What successful cases exist for localized production in emerging markets?

Step-by-step retrofit programs draw on extensive 5G Industrial IoT applications:

- Sensor installation for equipment connectivity

- Digital twin platforms for process optimization

- AI quality inspection systems

These upgrades increase efficiency by 20% with payback periods of less than two years.

What successful cases exist for localized production in emerging markets?

More than 10 localized lines have been established in Pakistan and Iran, featuring:

- Compact workshop layouts adapted to local conditions

- Equipment designed for high-temperature and dusty environments

- Lower tariffs and logistics costs by 30%

These help clients rapidly capture market share in new regions.

Under EU carbon tariff policies, how is low-carbon production achieved?

A green factory solution integrates:

- Waste-heat power generation from flue gas

- Real-time emissions monitoring

- BIPV rooftop systems

Certified as a National Green Factory, this solution enables 5,000 tons of carbon reduction per line annually.

Why choose BBKS?

- Holds 75% market share in China’s high-end glass equipment sector, serving over 100 lines worldwide

- Recognized by the Ministry of Industry and Information Technology as a demonstration enterprise for intelligent manufacturing

- Provides turnkey projects, from design and manufacturing to installation and long-term operation support

How does the float glass production line keep the cutting process?

How well does the rolled glass production line perform in terms of light transmittance?

What smart features does the electronic glass line include?

How is glass quality checked during production?

How are glass dimensions measured after cutting?

How is uniformity ensured in glass for electronic appliances?

What is the process flow of a float glass production line?

The float glass production line includes the melting furnace, tin bath forming, cooling, and cold-end systems. In the melting stage, equipment such as batch chargers, doghouse deep refiner carts, and stirrers are used. The forming stage uses edge-pulling machines in the tin bath. The cooling stage relies on annealing kilns, while the cold end includes conveyors, cutting machines, stackers, line control, and optimization systems.

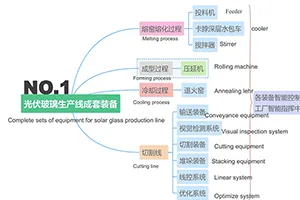

What is the process flow of a photovoltaic solar glass production line?

A photovoltaic solar glass production line includes the melting furnace, forming, cooling, and cutting stages. In the melting stage, batch chargers, doghouse feeders, and stirrers are used. In the forming stage, rolling machines shape the glass. During cooling, it goes through annealing kilns, which remove internal stress and make the glass sheets more stable. The cutting line is equipped with conveyors, visual inspection systems, cutting machines, stackers, line control, and optimization systems.

What glass sizes can the automatic packaging line handle?

How does the batch charger keep the feeding steady?

What makes the dross box safe to use?

How does the solar glass rolling machine last longer under high heat?

How does the glass stirring system keep the glass uniform?

What role does the optimized cutting system play during glass cutting?

How does the shuttle conveyor system ensure safety during glass transportation?

How is accuracy maintained in robotic glass loading and unloading?

How does the solar glass washing machine ensure the required level of cleanliness for different process stages?

How is stable operation ensured in fully automatic packaging lines for entire glass stacks?

How does the AGV glass transport system help reduce costs while maintaining high efficiency?

Wherever you are, we’re here to provide support and solutions. Share your inquiries with us—we look forward to collaborating with you.