Glass Silica Sand Processing Equipment used in Glass Manufacturing Process

Glass Sand Processing Equipment

Ore storage hopper

Ore storage hopper Hydraulic classifier / Hindered settling machine

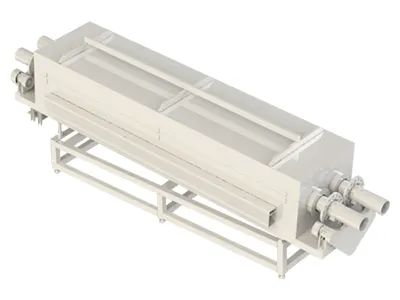

Hydraulic classifier / Hindered settling machine Attrition Scrubber (Glass Sand Scrubbing Machine)

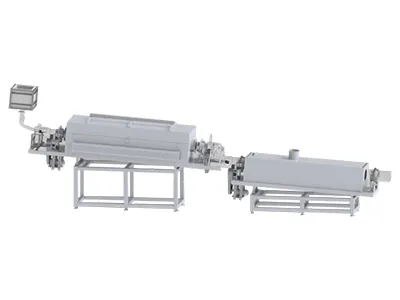

Attrition Scrubber (Glass Sand Scrubbing Machine) Continuous Flotation Machine

Continuous Flotation Machine

High-Purity Glass Sand Processing Equipment

Double Cone Vacuum Dryer/Blender

Double Cone Vacuum Dryer/Blender Self-Priming Flotation Cell

Self-Priming Flotation Cell Double-tube water quenching furnace

Double-tube water quenching furnace Chlorination furnace

Chlorination furnace

Pressure Vessels

Air Storage Tank

- Design pressure: -0.1 MPa to 100 MPa br

- Design temperature: -100 °C to 400 °C

- Applicable media: Air, natural gas, nitrogen (N₂), carbon dioxide (CO₂), carbon monoxide (CO), hydrogen (H₂), and other industrial gases

- Material options: Carbon steel, stainless steel, and composite plates

Reactor (Chemical Vessel)

- Design pressure: -0.1 MPa to 100 MPa

- Design temperature: -50 °C to 400 °C

- Applicable media: Lipids, alcohols, phenols, oxides, alkalis, acids, and other chemical materials

- Diameter range: 500 mm to 4000 mm

- Material options: Carbon steel, stainless steel, titanium alloy, stainless steel-clad plate, nickel-steel clad plate, titanium-steel clad plate, and more

- Agitation types: Paddle, anchor, frame, ribbon, turbine, dispersing disc, and combined structures

- Heating methods: Thermal oil circulation, jacketed electric heating, steam heating, hot water heating, and water cooling

- Heat transfer structures: Outer jacket, external half-pipe, and internal coil

Gas Distributor

Gas Distributor Heat Exchanger

Heat Exchanger Filter

Filter