Architectural glass production lines take raw glass sheets and turn them into glass products ready for use in buildings. The glass goes through steps like cutting it to the right size, smoothing the edges so they’re safe to handle, giving it a good clean, and adding treatments that make buildings safer and help save energy. With architectural glass production lines, it’s possible to produce glass for building façades, windows, doors, and even interior partitions, combining strength, durability, and appearance to match the needs of modern construction.

Architectural Glass Production Equipment

Raw Material Handling and Forming

- Furnaces for melting glass

- Drawing equipment for shaping glass sheets

- Annealing kilns to release internal stress

Cutting and Edging

- Automatic glass cutting machines

- Horizontal edging machines for all four sides

- Break-out machines for sheet separation

Washing and Drying

- Horizontal washing and drying machines

- Special cleaning machines for Low-E glass

Deep Processing Equipment (by product type)

- Tempered glass production line

Tempering furnace

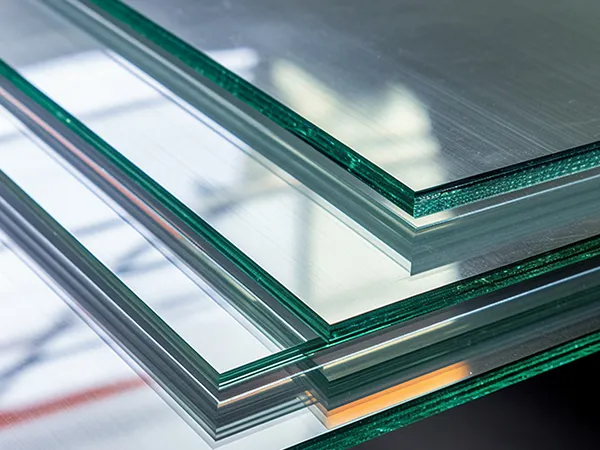

Continuous quenching equipment - Laminated glass production line

Laminating machine

Pre-press machine

Autoclave - Insulating glass production line

Butyl coating machine

Two-component sealant machine

Desiccant filling unit + argon gas filling - Energy-saving glass equipment

Offline coating machine

Bending furnace

Quality Inspection and Auxiliary Equipment

- Online inspection system

- Automatic loading/unloading tables

- Specialty gas stations and exhaust treatment equipment

Packaging and Storage Equipment

- Automatic packaging lines

- Intelligent storage systems