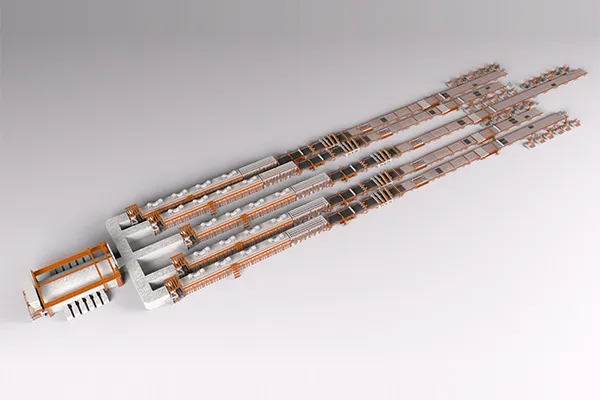

Rolled Glass Production Line

Complete line for manufacturing solar glass, ornamental glass and patterned glass

Rolled glass is made by passing molten glass through rollers that shape it into sheets with specific patterns or textures. This process is commonly used to make solar glass for photovoltaic panels, decorative panels with frosted or embossed surfaces, glass for partitions, BIPV applications, and ultra-clear rolled glass. The rolled glass production line can produce glass sheets between 2.0 mm and 3.2 mm thick and up to 3300 mm wide. Rolled glass is widely used in solar energy because its textured surface improves light scattering, helping solar cells absorb more energy.

-

Batch Charger (Glass Furnace Feeder)

Batch Charger (Glass Furnace Feeder) -

Glass Rolling Machine

Glass Rolling Machine -

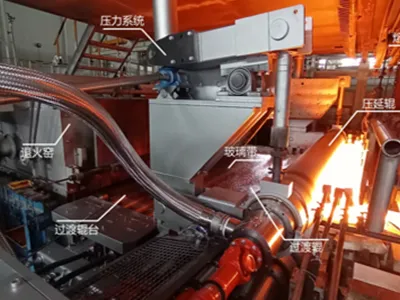

Glass Annealing Lehr

Glass Annealing Lehr -

Cold End Equipment (glass cutting, glass conveying, glass stacking, etc.)

Cold End Equipment (glass cutting, glass conveying, glass stacking, etc.)