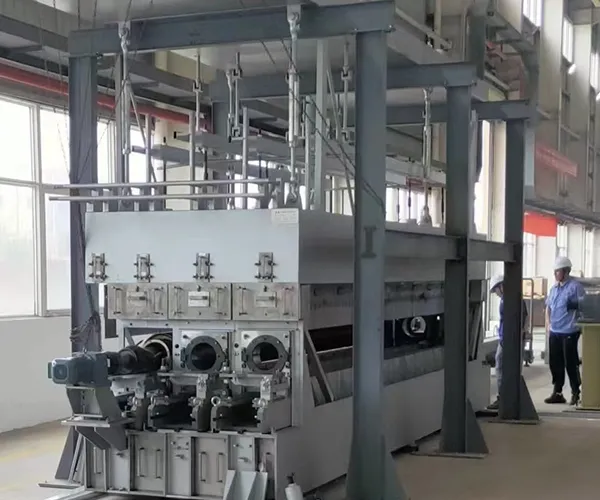

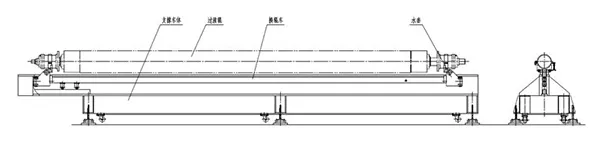

Dross Box (with Lift-Out Roller)

Sealed transition chamber for transferring glass ribbon from the tin bath to the annealing lehr

In flat glass production, the dross box (with lift-out roller) is positioned between the tin bath and the annealing lehr. Its main function is to seal the end of the tin bath, preventing protective gases inside the bath from leaking out and blocking external air from entering. At the same time, it transfers the glass ribbon from the tin bath into the annealing lehr for the next stage of processing. This point in the production process poses particular challenges, because the glass ribbon, which is still very fragile, requires the utmost precision in handling under extreme ambient conditions.

From a process perspective, the dross box links two key thermal systems, the tin bath and the annealing lehr. Operating at temperatures between 600 °C and 700 °C, it is the critical zone where glass transitions from a highly viscous plastic state to the initial elastic state. The stability and sealing performance of this chamber are essential to maintaining product quality and ensuring smooth process continuity.

- Production capacity: 1200t/d (max. raw sheet width 5.8m, min. sheet thickness 0.12mm)

- Glass pull rate: 30-1200t

- Glass thickness: 0.12-19mm

- Glass width: 4-5.8m

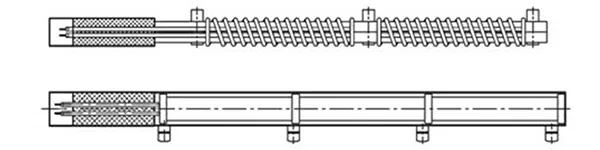

Easier and safer roller replacement

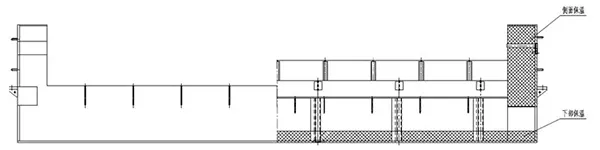

Improved sealing performance, combining side insulation and bottom insulation methods

Controllable internal temperature, combining upper heating and bottom heating methods