Paper Laying Machine for Glass Sheets

Paper insertion machine for placing glass separation paper between two glass sheets

The paper laying machine automatically inserts separation paper between consecutive glass sheets to prevent scratching and surface damage during storage or transport. By adding these protective layers, the glass can be shipped directly to end customers in a ready-to-use condition. The inserted paper strips also make handling more convenient, allowing operators to grip and separate individual glass sheets with ease when unloading from storage racks.

The offline paper laying machine adopts a six-axis robotic arm that can operate in both upward and downward gripping modes. It automatically positions glass sheets horizontally before initiating precise and efficient paper placement, achieving fully automated separation paper application.

- Power: 5.2kW

- Working pressure: 0.6MPa

- Working accuracy: ±2mm

- Working efficiency: 8 sheets/min

- Glass sheet thickness: 1.6-4mm

- Max. glass sheet size: 2600×1400mm

- Min. glass sheet size: 1200×600mm

The online paper laying machine enables continuous paper insertion for solar glass without stopping the production line. It can flexibly cut paper lengths according to the size of the glass sheets. Equipped with either parallel or series dual paper-roll structures, it ensures uninterrupted operation, with one roll serving as backup, enabling faster paper replacement and stable continuous production.

- Power: 21kW

- Working pressure: 0.4-0.7MPa

- Working accuracy: ±3mm

- Working efficiency: 16.5 sheets/min

- Glass sheet thickness: 1.6-4mm

- Max. glass sheet size: 1400×300mm

- Min. glass sheet size: 600×600mm

High-speed operation

High-speed operation

The system lays paper along the long edge of the glass while the sheets remain in motion, achieving automatic feeding with a cycle time of more than 15 sheets per minute. Efficient paper utilization

Efficient paper utilization

By adopting a longitudinal paper-laying process, the system minimizes the need for multiple paper roll specifications. This maximizes paper usage, improves adaptability, and lowers production costs. User-friendly operation

User-friendly operation

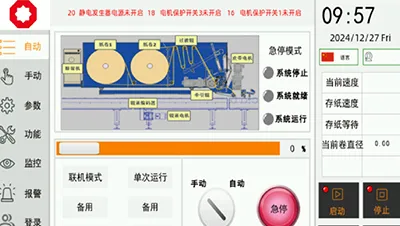

Designed with operator habits in mind, redundant functions and complex procedures have been eliminated. The control layout has been restructured for intuitive use, ensuring simple and efficient operation. High precision

High precision

The third-generation offline paper laying technology integrates a high-precision servo-driven traction mechanism and high-speed rotary cutting. This ensures consistent feeding, neat cuts, and a paper-laying accuracy within ±2 mm.