Glass Loading and Unloading Robot

Automatic glass handling system with robotic arms for loading and unloading of glass sheets

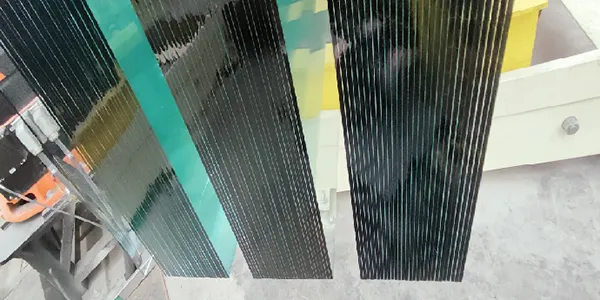

The glass loading and unloading robot is designed to manage multiple glass formats, including both long and short edges, during flat glass production. It enables flexible stacking and de-stacking operations with high efficiency. Featuring robotic arms equipped with advanced gripping technology, the system transfers glass sheets from the conveyor to designated racks or from racks onto the conveyor line. With its no-downtime flying grip mechanism and dual-sheet handling capability, the robot significantly boosts production efficiency while ensuring stable and precise glass handling.

| Load capacity of robotic arm | 210/360/420/500kg |

| Glass sheet size | 3660×2800mm (max. size),600×600mm (min. size) |

| Glass sheet thickness | 1.6-15mm |

| Stacking capacity | 1 sheet pickup:≥8 seconds |

| 2 sheets pickup (same stack):≥15 seconds | |

| 2 sheets pickup (different stack):≥16 seconds | |

| Stacking accuracy | ±1.5mm |

| Pickup method | Top side pickup (air side pickup),bottom side pickup (tin side pickup) |

| Max. stacking depth | 800mm |

| Loading capacity of rotating platform | Float glass line:4.5t Rolled glass line:3.5t |

| Stacking cycle time | Float glass line:10s Rolled glass line:8s |

| Number of classification grades | Stacking can be done in up to 5 grades |

Book-style stacking precision

Equipped with our proprietary edge-measurement algorithm, the robot continuously adjusts its stacking posture in real time. This ensures alignment accuracy between adjacent glass sheets within ±1.5 mm.

Faster stacking cycle

Integrated sensor technology and vision recognition allow for precise positioning of glass sheets, minimizing search and alignment time to accelerate production cycles.

Flexible glass handling and pickup methods

The loading and unloading robotic system supports a variety of handling methods to meet different operational needs:

- Static upper-level pickup

Glass sheets can be removed from the upper tier when the line is stationary, ensuring accurate and stable handling. - Static lower-level pickup

Sheets can also be taken from the lower tier in static mode, giving flexibility to manage different production requirements. - Single sheet pick on the fly

The robot synchronizes with the moving line to remove one glass sheet without interrupting production flow. - Dual sheets pick on the fly

Two sheets can be removed simultaneously while the line is running, ensuring greater efficiency.