Glass Sheet Transport Shuttle System

Multi-level glass storage and conveyor system for the continuous transport of glass sheets between two floors

The glass sheet transport shuttle system is a multi-level storage and conveyor solution designed for the continuous vertical transfer of glass sheets between two floors. It consists of the second-floor storage conveyor, lifting conveyor, first-floor storage conveyor, and an automated electrical control system. By combining the large loading capacity of mobile glass storage racks with the flexibility of a rack shuttle system, it enables uninterrupted reloading and the efficient transfer of glass from the upper production line to the lower one, completing a fully automated flat glass production process. The result is a production environment that is both efficient and reliable, supporting stable operation even in demanding conditions.

- Power: 29.1kW

- Working pressure: 0.6MPa

- Working accuracy: ±3mm

- Max. lifting speed: 1.1m/s

- Glass sheet size (W×L): (1000-1600)×(1417-3047)mm

- Glass sheet thickness: 1.6-4mm

- Max. load capacity: 1500kg

Features

Enhanced safety

Enhanced safety

Equipped with multiple safety protection mechanisms, including protective barriers, motor overload protection, and emergency braking devices. Real-time monitoring of glass positioning in both horizontal and vertical directions ensures the system remains safe for both operators and equipment. User-friendly operation

User-friendly operation

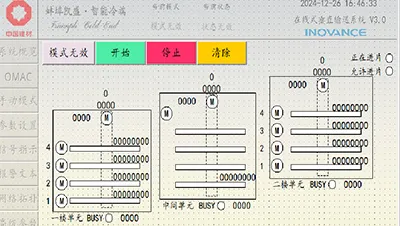

The system incorporates a PackML-based process management control system, developed for solar glass shuttle conveyors. By optimizing workflow operations, it enhances efficiency and simplifies control. Intelligent fault detection

Intelligent fault detection

A real-time belt monitoring system scans the status of each transmission layer. If a damaged belt is detected, the system automatically bypasses it and continues production using the next available layer, ensuring uninterrupted operation.