System Components

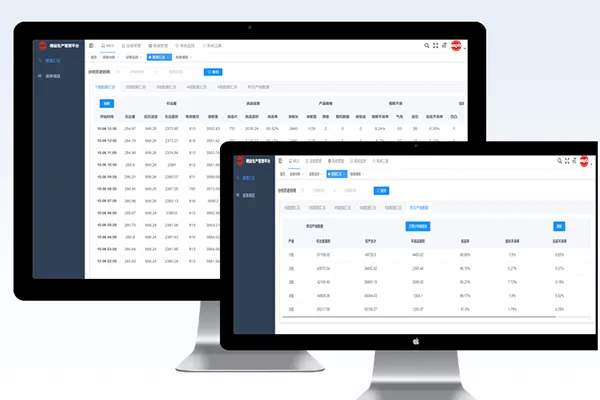

Data Collection and Visualization Scheduling System

Collects data from glass equipment, production processes, and energy use into one system, creating a real-time monitoring center for the factory. The data collection and scheduling system allows users to view operations in both 2D and 3D, so it’s easier to follow what’s happening on the factory floor in a clear and practical way.

Production Management System

Handles the entire process from importing sales orders to intelligent scheduling, process monitoring, output statistics, and yield analysis. It also includes functions such as automated reporting, data alerts, and parameter adjustments.

Warehouse Management System

The system manages the entire warehouse process in a digital way, covering everything from raw material storage and semi-finished transfers to finished goods delivery. The RFID and barcode tracking function keeps inventory visible and under control, ensuring that materials can be easily traced and managed throughout the entire warehouse process.

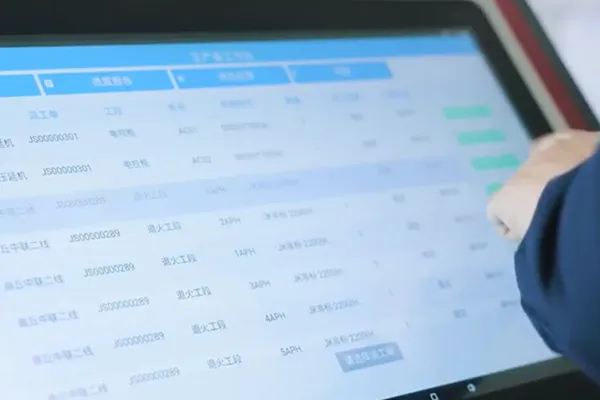

Equipment Lifecycle Management System

Manages the entire lifecycle of equipment, from procurement to decommissioning. The system supports predictive maintenance and includes a knowledge base for repair and service, helping factories extend equipment lifespan, reduce downtime, and optimize long-term operational efficiency.

Energy and Cost Management System

The system keeps track of electricity, water, gas, and fuel in real time. It uses this data together with process parameters to work out the cost of each product. This gives a clearer view of energy use and helps bring down both consumption and costs.

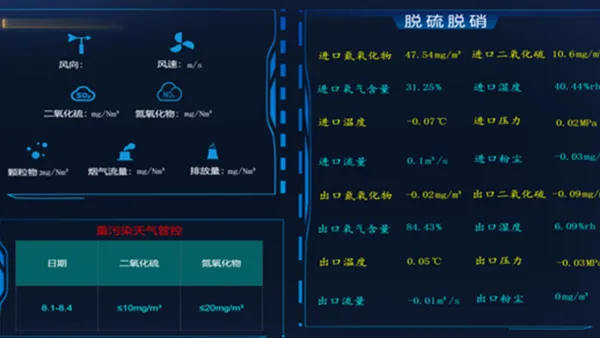

Safety and Environmental Management System

Builds a framework for work permit management, environmental monitoring, and emergency alerts to ensure safe production and compliance with environmental regulations.

Glass Production Quality Management (Visual Inspection System)

Performs real-time inspection during glass conveying, automatically classifies products, and provides full traceability for each piece of glass.

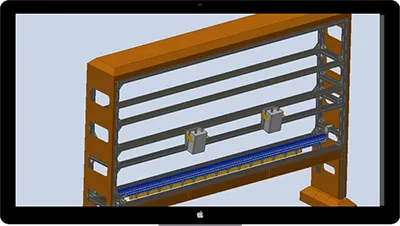

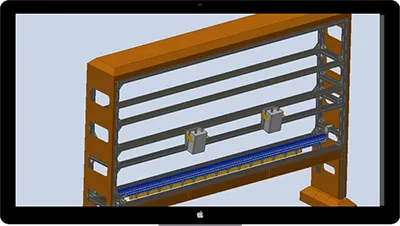

Glass Ribbon Positioning and Cutting Inspection System

Checks the alignment of the cutting system, including blade position and starting point, to ensure precise and automated cutting of glass sheets.

Integrity and Dimension Inspection System

Checks the size and overall condition of the glass after cutting to make sure each piece meets the required standards.

Glass Defect Detection

Uses visual recognition to identify defects such as bubbles and scratches. Combined with data analysis, it automatically detects and classifies different types of flaws.